3D-PRINT TECH approached Formfutura if we could sponsor and advice filaments for their DIY 3D printer project. The chosen materials are ReForm rPET and ReForm rTitan.

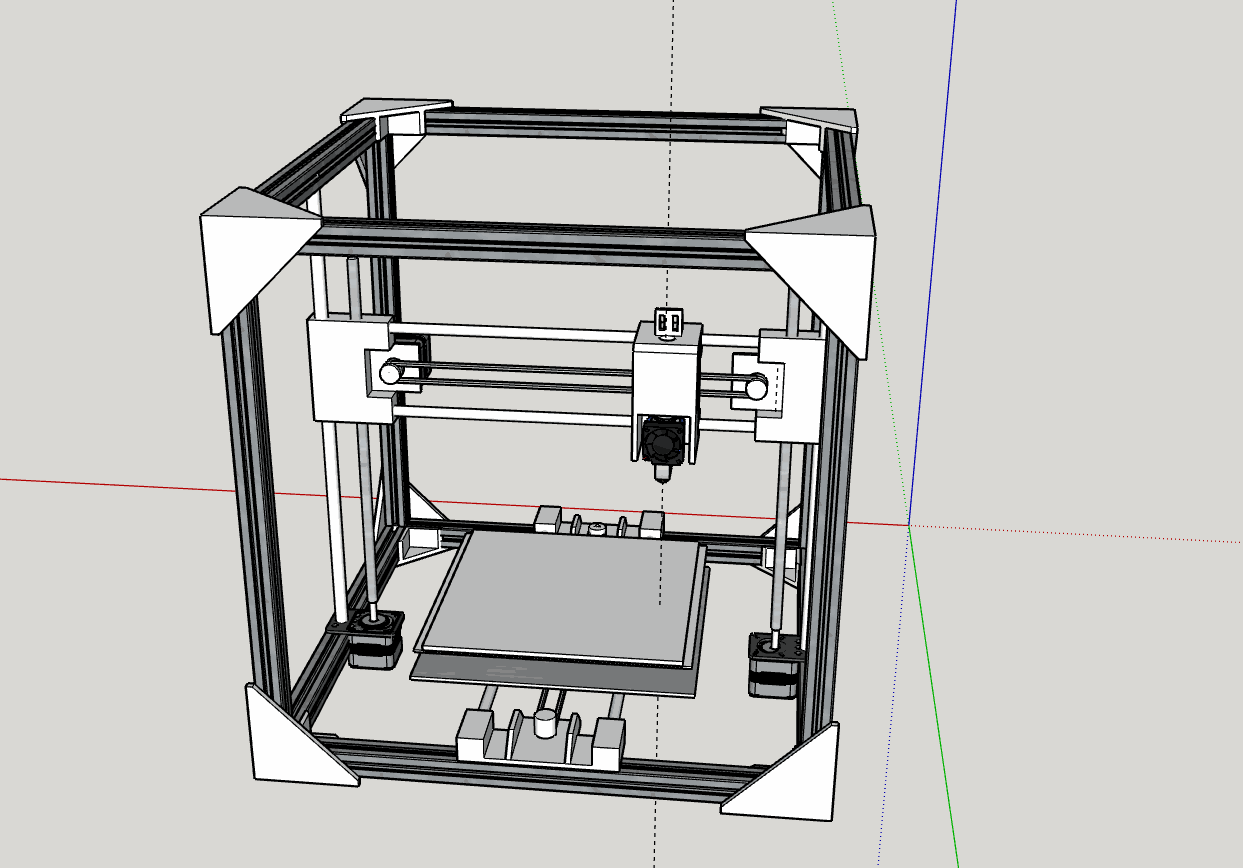

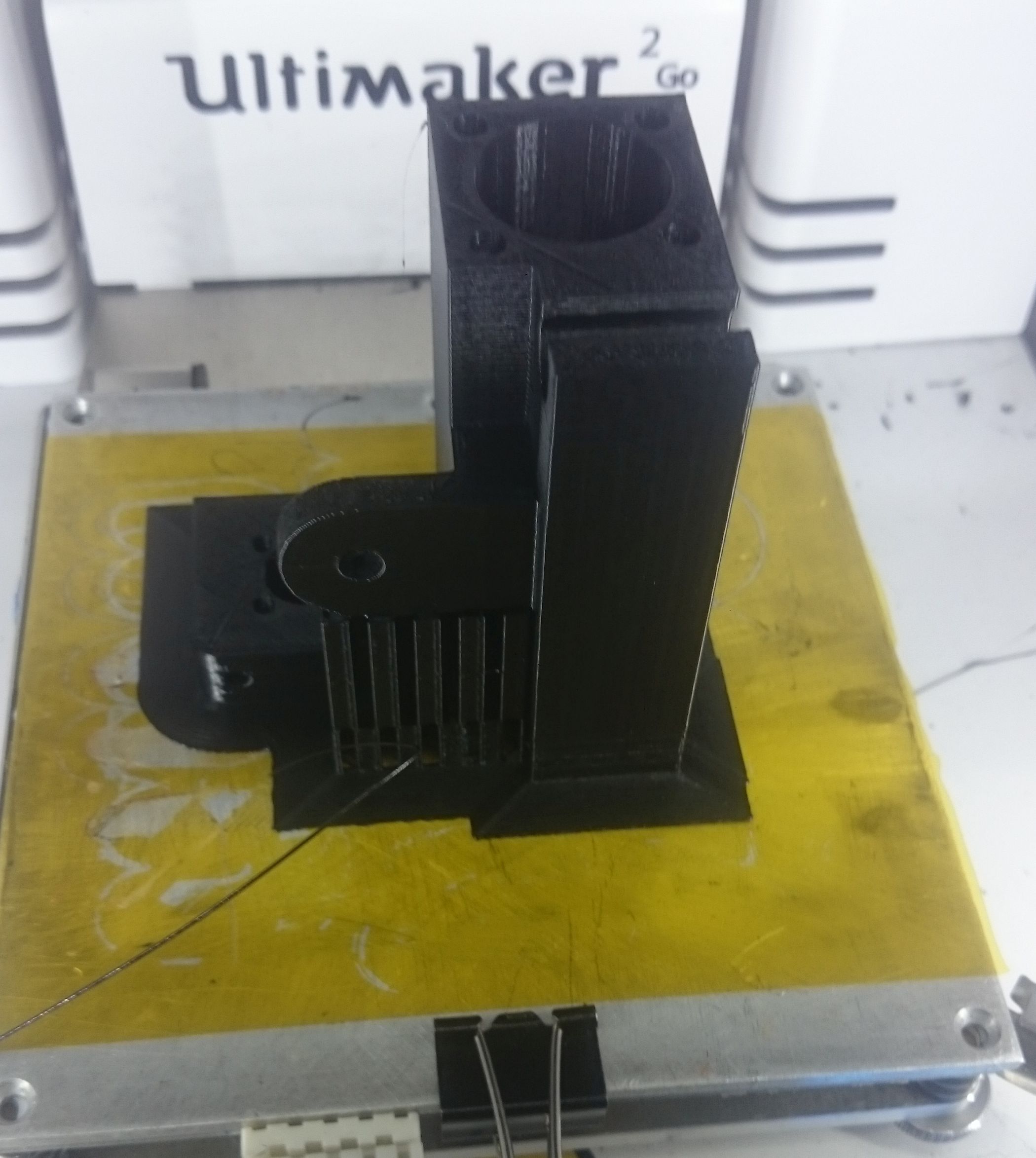

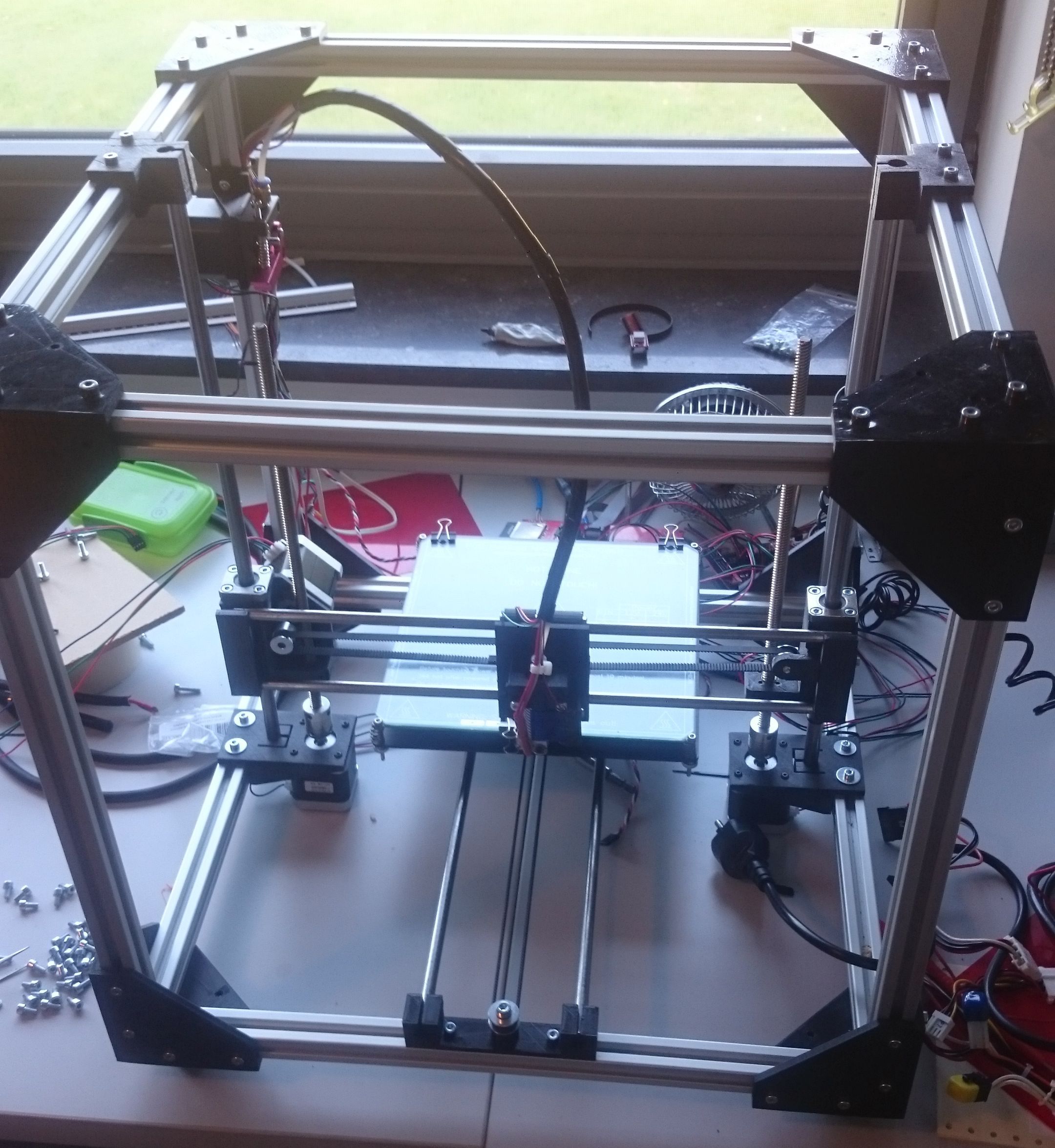

3D-PRINT TECH is currently building their own 3d printer. Their goal is to use 3D printed parts whenever possible. The 3D printed parts will be printed on a Ultimaker 2 Go with heated bed.

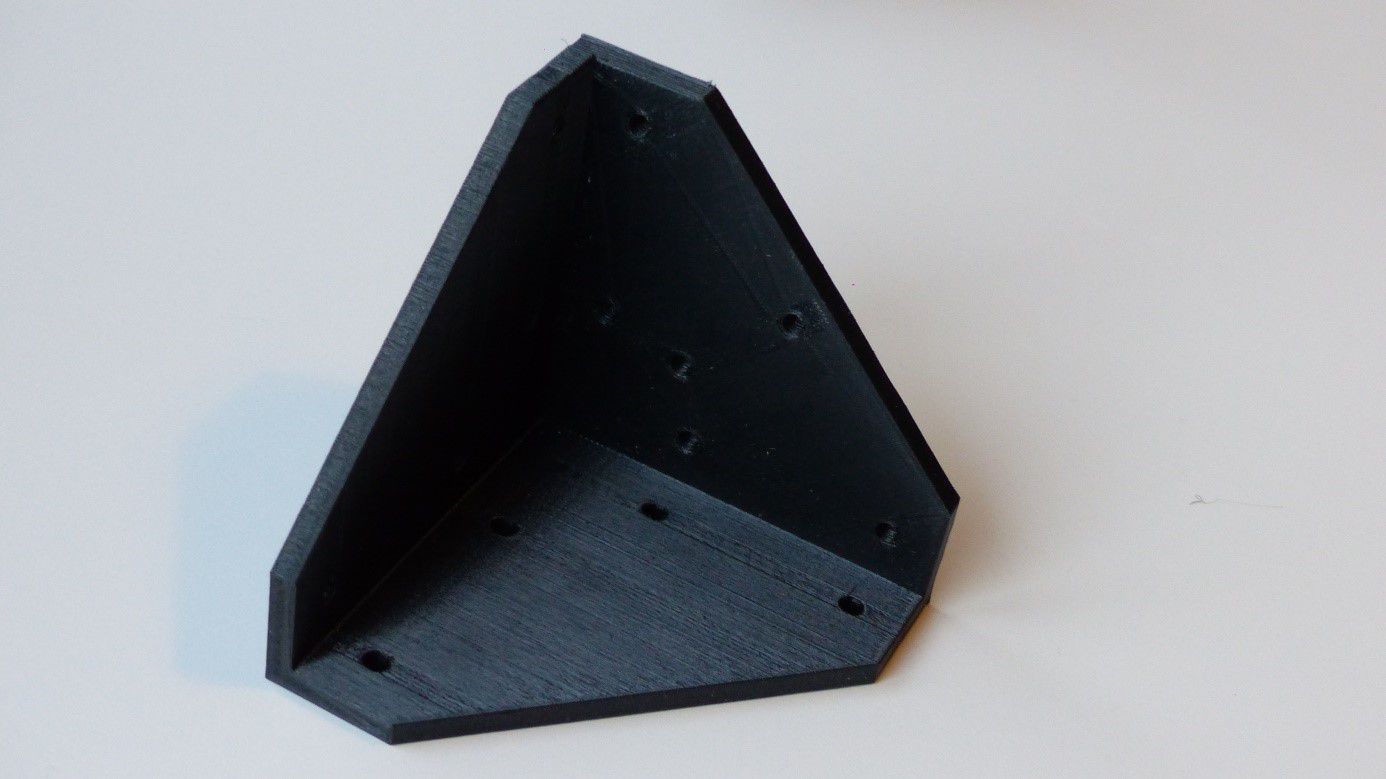

All of the brackets, motor mounts, housings and corner brackets will be 3d printed.

During the design process 3D-PRINT TECH realized that they couldn’t use normal PLA for the mechanical parts and had to search for stronger and more impact resistant materials. The parts have to be strong and temperature resistant as they will be near heat sources like the hot end and the heated print bed.

In order to find these materials 3D-PRINT TECH reached out to Formfutura for sponsoring and advice. The recommended and chosen filaments for this project are ReForm rPET and ReForm rTitan. Both materials combined offer all mechanical and thermal properties needed for 3D printing the mechanical parts.

3D-PRINT TECH specifically choose for ReForm filament because it is a recycled filament range made from residual waste streams of the extrusion processes of respectively HDglass and TitanX filaments. 3D-PRINT TECH really liked the idea of doing the DIY 3D printer project using ReForm filaments, because the filament is made from upcycled extrusion waste streams, is cheaper than virgin grade filaments and has a lower carbon footprint than virgin grade filaments. Although the recycled ReForm filament is cheaper Formfutura certainly didn’t sacrifice quality.

ReForm filaments come on thick cardboard spools which actually are stronger than some of the plastic spools available in the market.

ReForm rTitan is the toughest of the two materials and ReForm rPet is a little bit more flexible.

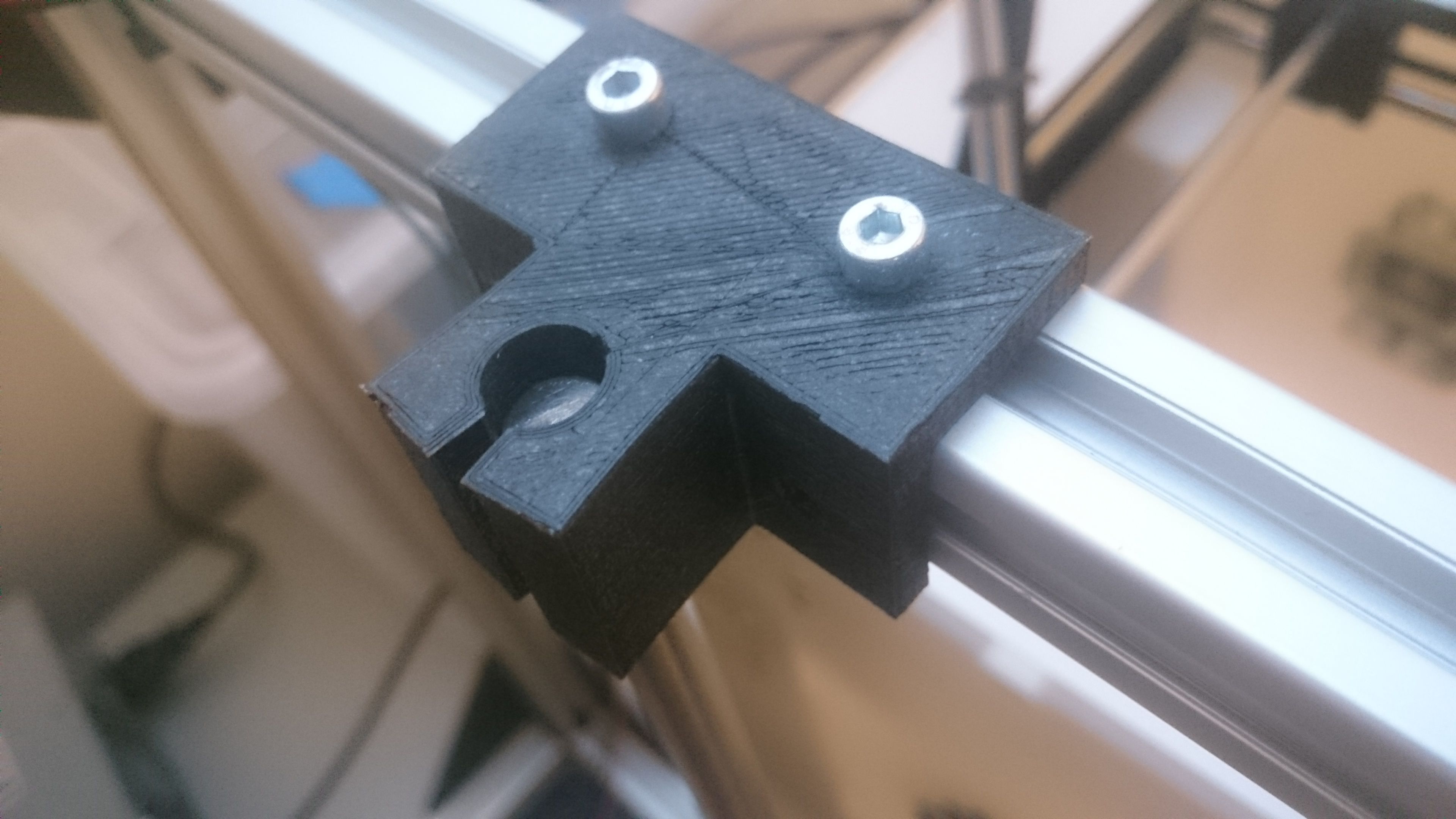

3D-PRINT TECH used rTitan for the corner brackets because these have to be very stiff. If one of the brackets would bend a little everything gets out of alignment.

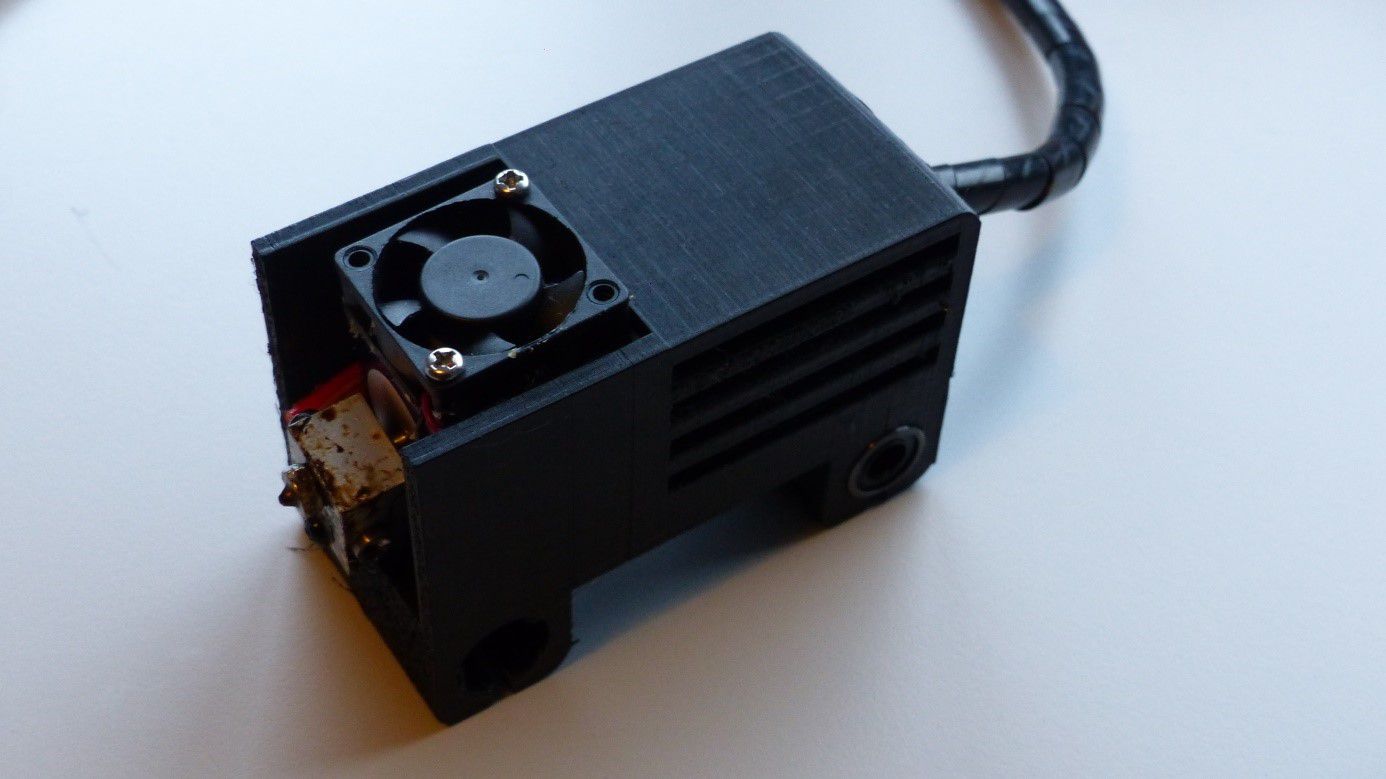

3D-PRINT TECH also used rTitan for the print head- housing because rTitan has a high softening temperature of 97°C.

ReForm rPET is used for the parts that clamp the linear rod’s, because rPET will bend instead of break.

It is 3D-PRINT TECH’s experience that both materials print very well. The ReForm rPET can be a bit “stringy” if retraction settings aren’t enabled. After raising the retraction length the stringiness was acceptable. When printing multiple parts on the platform stringing can occur when the printhead is moving from one part to the other part. The little wisps of filament between two parts can be easily removed though with a little knife.

The experience with rTitan is that the filament has great interlayer adhesion, better than most of the brands of ABS that 3D-PRINT TECH has worked with before.

ReForm rTitan is an engineering material that is a special compound containing 4 polymers other than ABS and impact modifiers, hence these great characteristics. It also warps far less than normal ABS, in most cases it doesn't warp at all.

There are a lot of parts that have been printed already but haven’t mounted to the frame yet, because they need some minor adjustments.

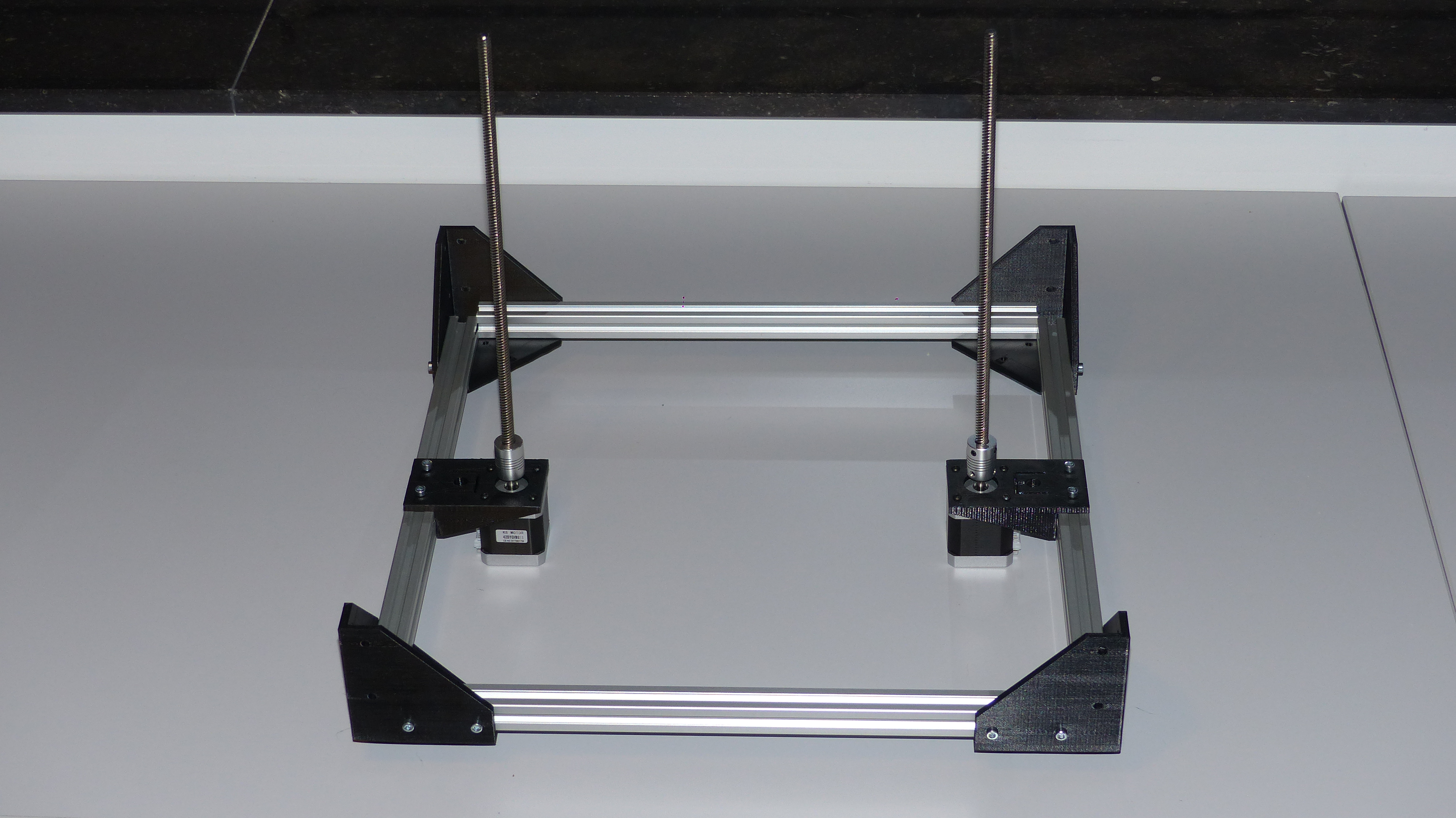

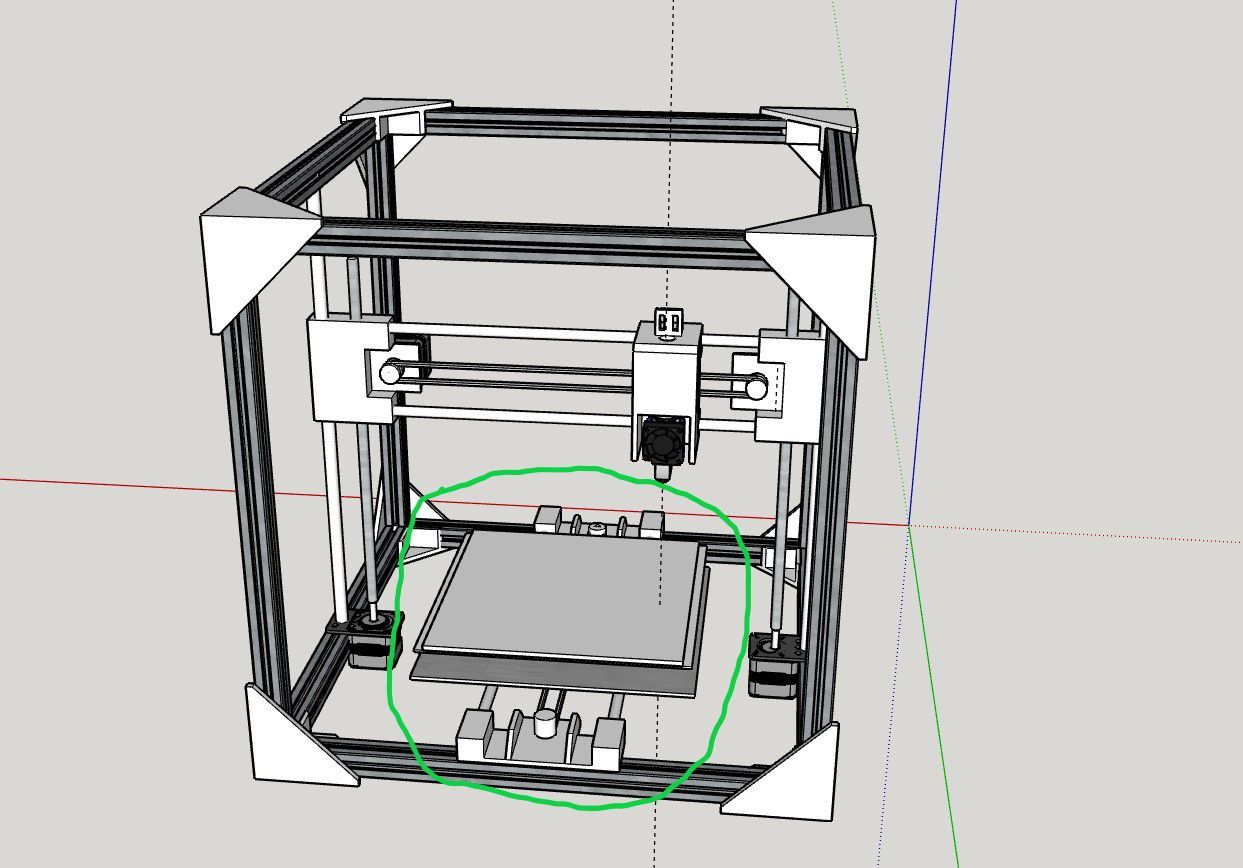

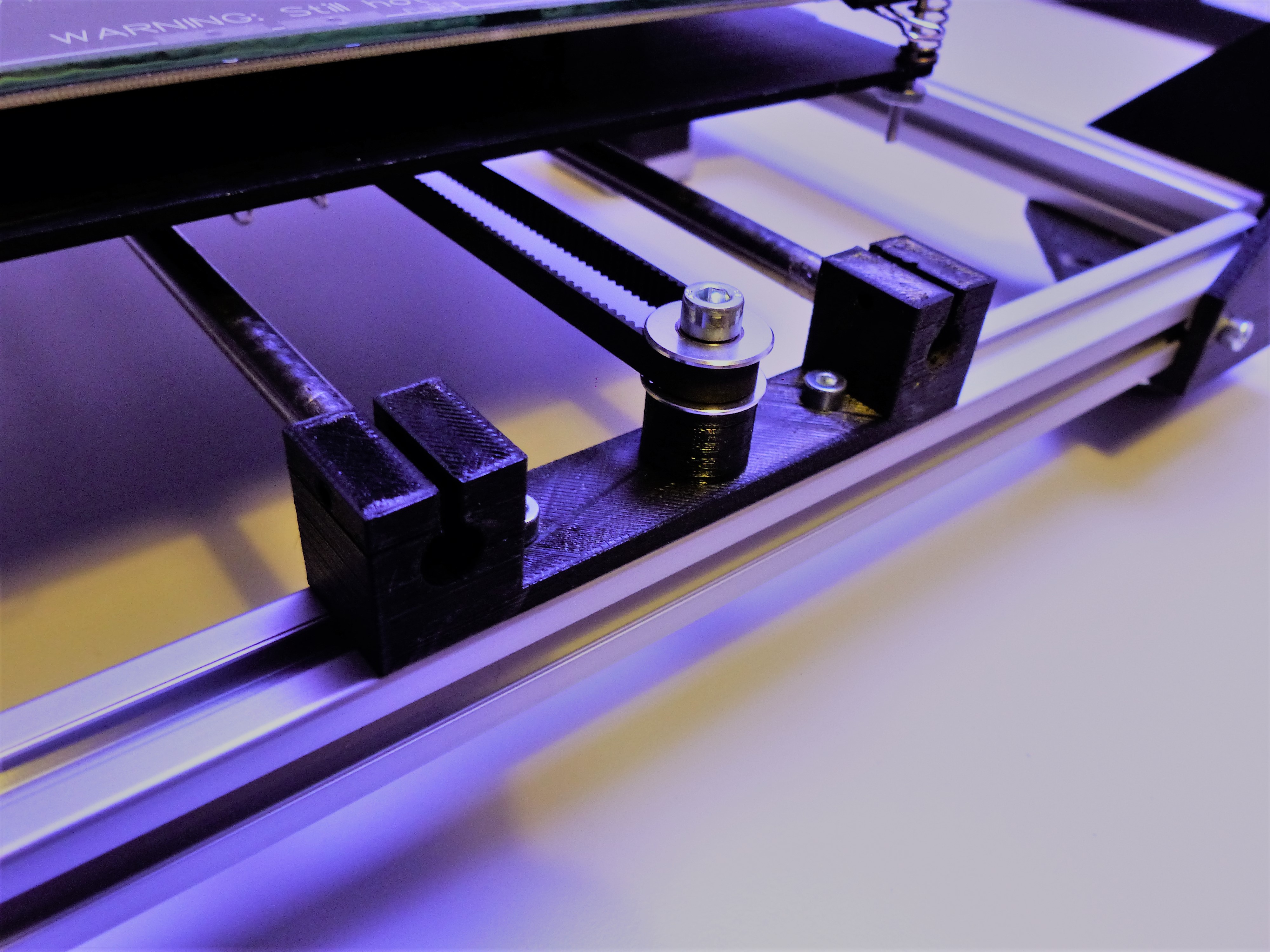

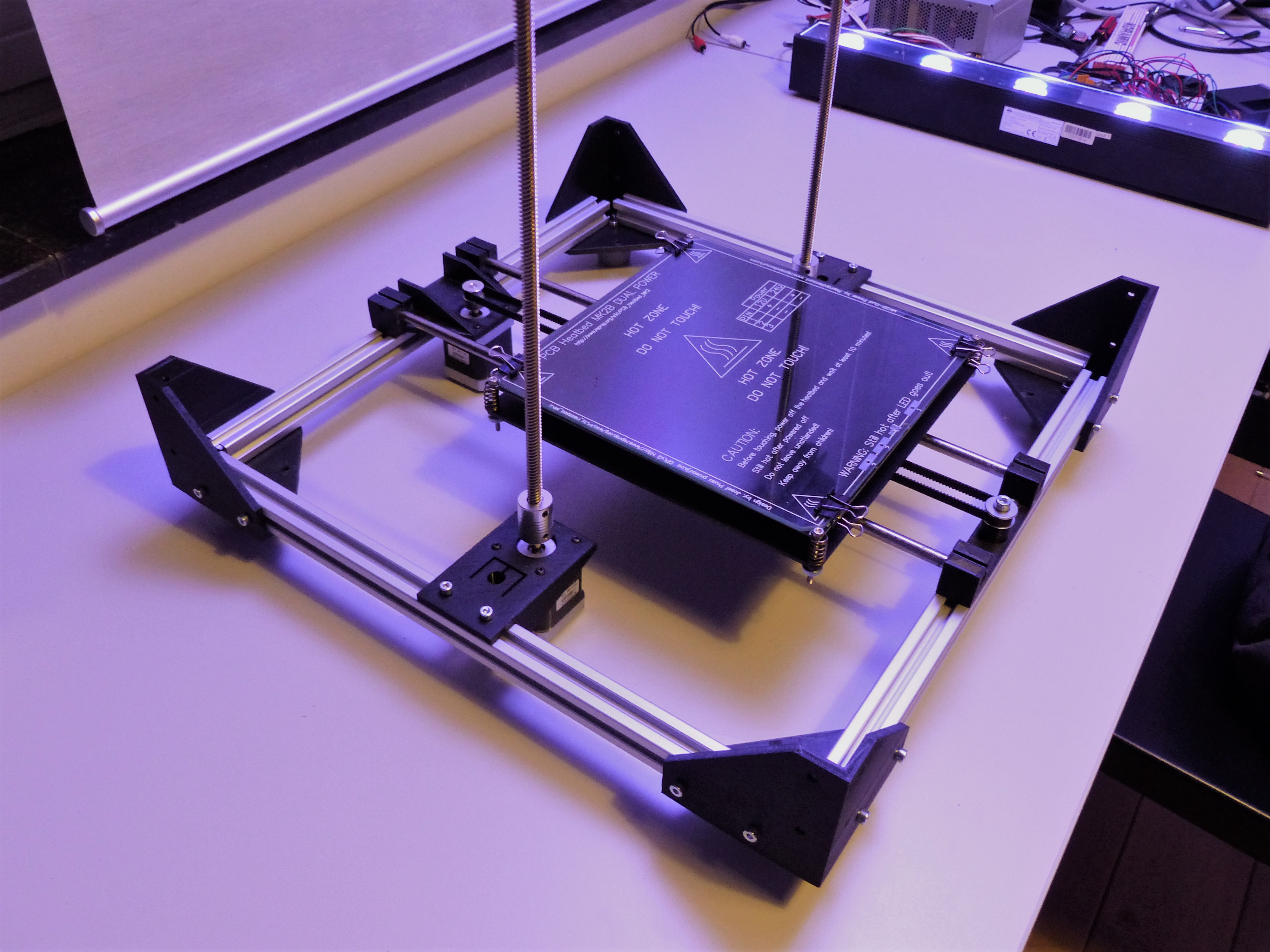

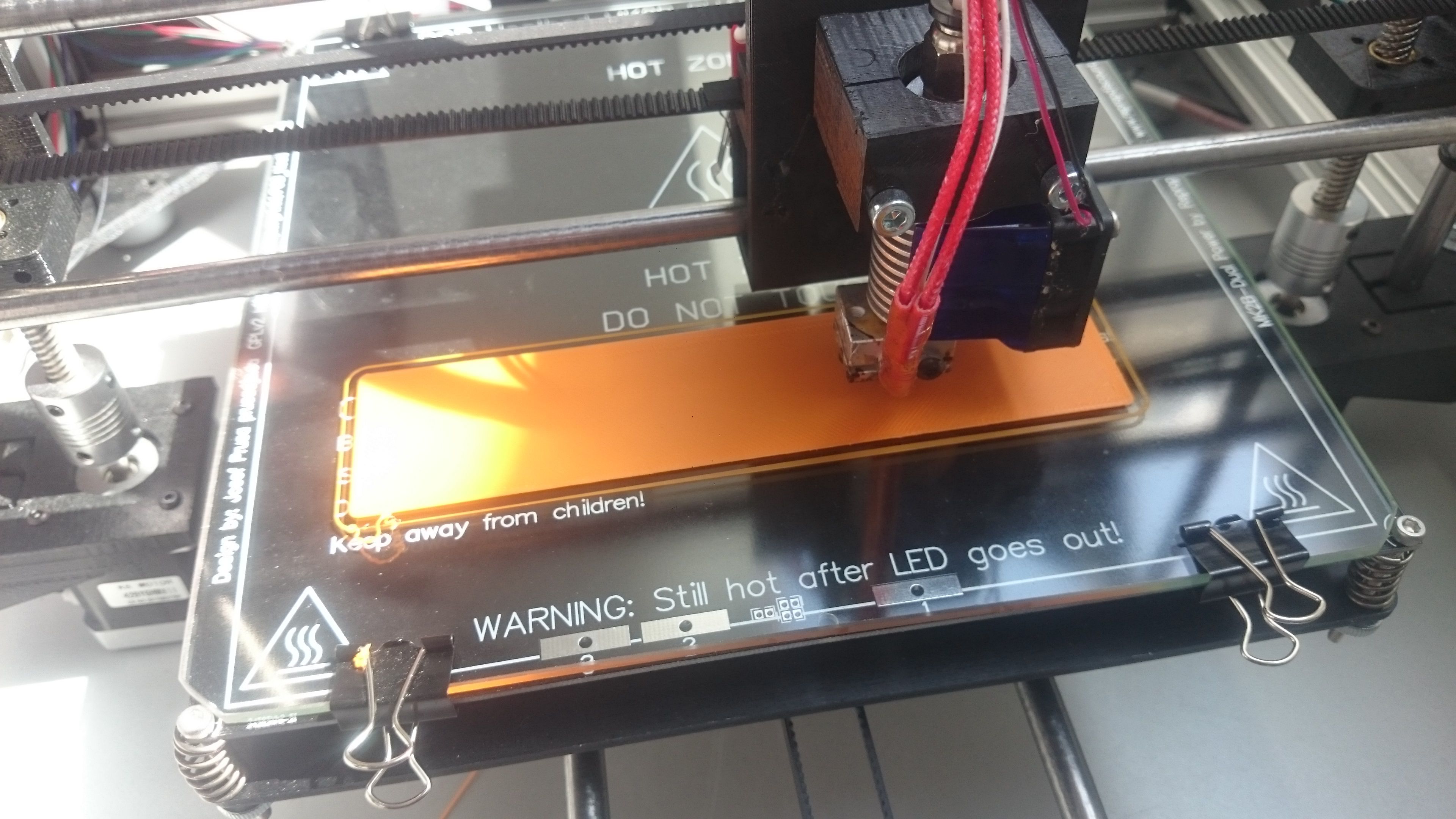

Now that all bottom parts have been printed and assembled the next objective of 3D-PRINT TECH was to assemble the print bed gantry.

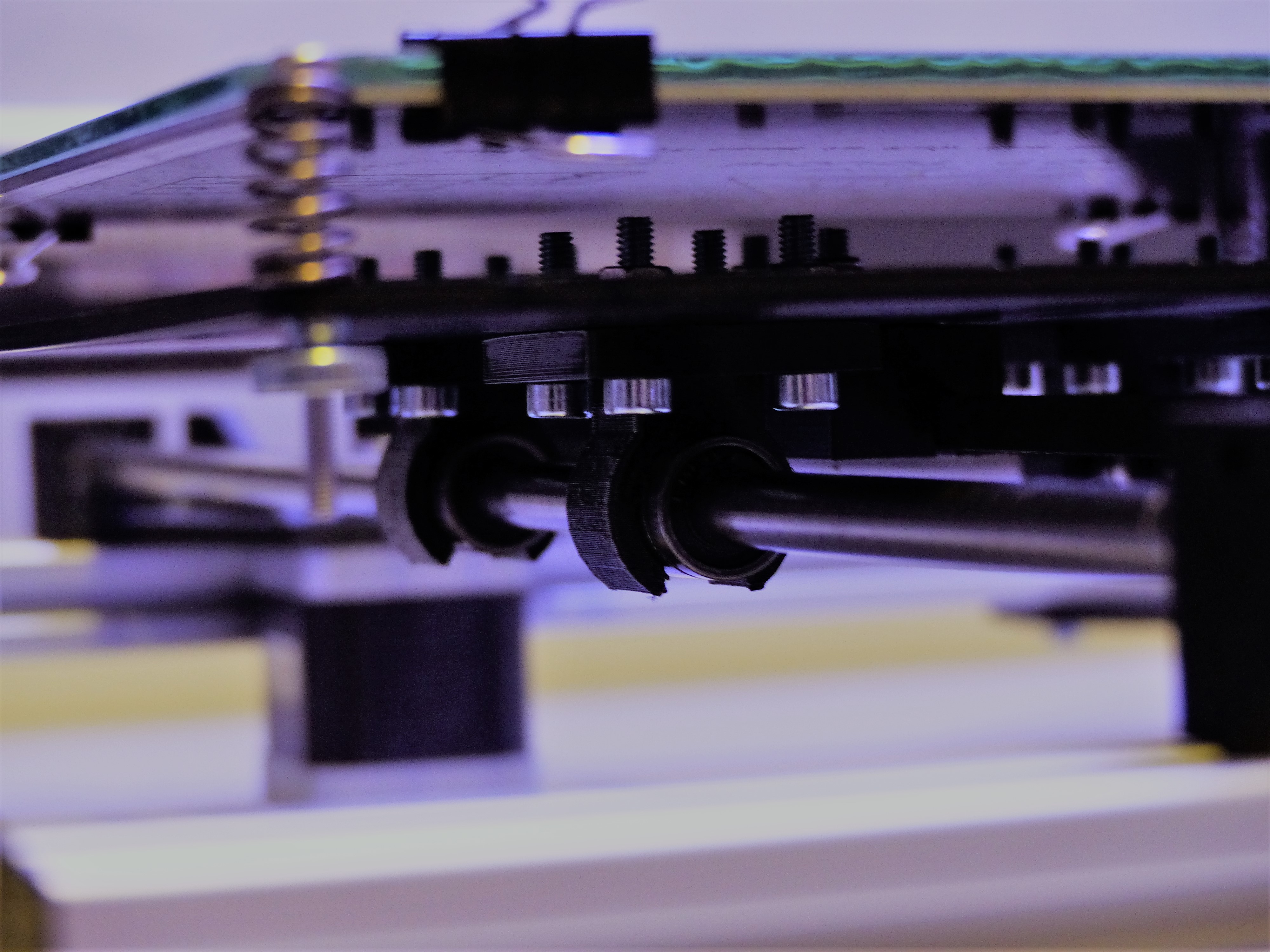

The print bed gantry is one of the more difficult parts of the printer because it is quite large and heavy. This means that the linear rods have to be quite far apart and running perfectly parallel to ensure a stable motion platform. The first parts printed by 3D-PRINT TECH were the linear bearing holders, these are attached to the bottom of the print bed and hold the bearings that move along the linear rods.

These parts have to fit very snugly, this meant that the tolerances where so small that most ReForm rPET prints cracked after inserting the bearing. Therefore 3D-PRINT TECH chose to use Python Flex filament as the flexible properties of Python Flex allow it to “flex” around the part and hold it in place perfectly.

The printed parts are attached to the metal plate underneath the heated bed of the 3D printer, which will get quite hot. With a heat deflection temperature of 138°C Python Flex has an exceptional resistance to heat and ensures that these parts attached to the heated bed won’t get soft nor deform.

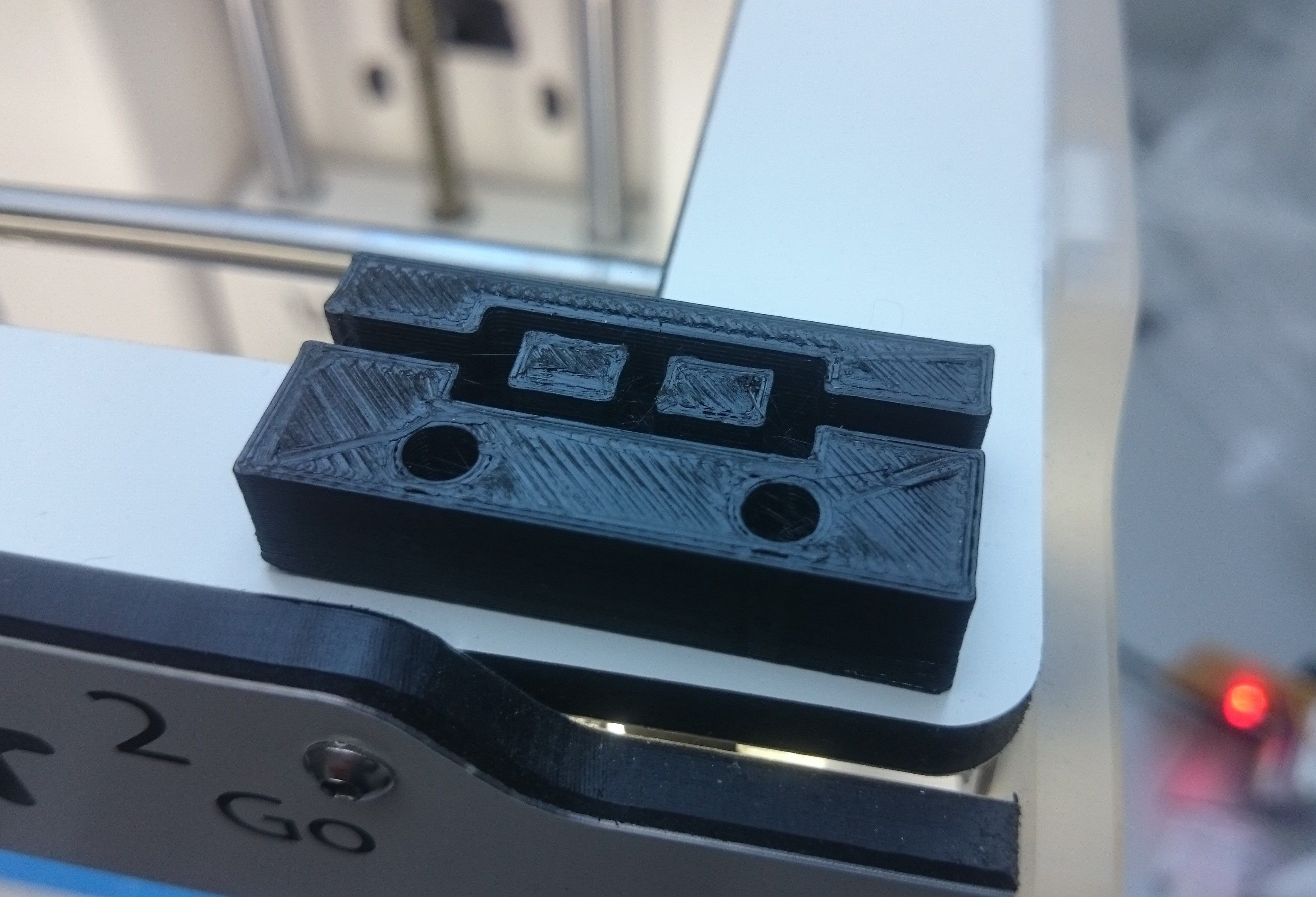

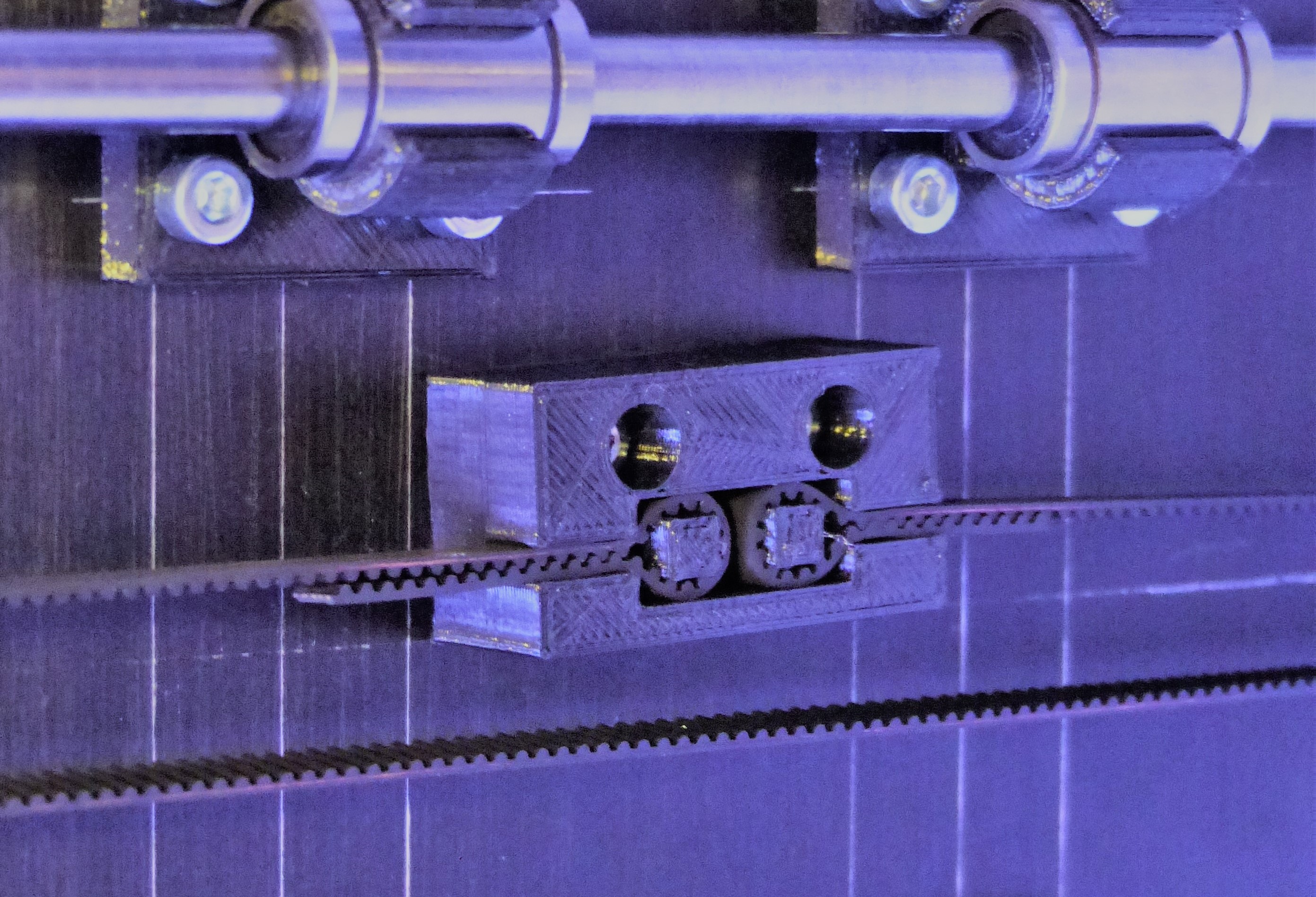

The last part that is attached underneath the print bed is the belt clamp. Both ends of the drive belt come in at each side and loops around the block in the middle.

3D-PRINT TECH designed this part to make the teeth of the belt catch in the teeth of the returning belt.

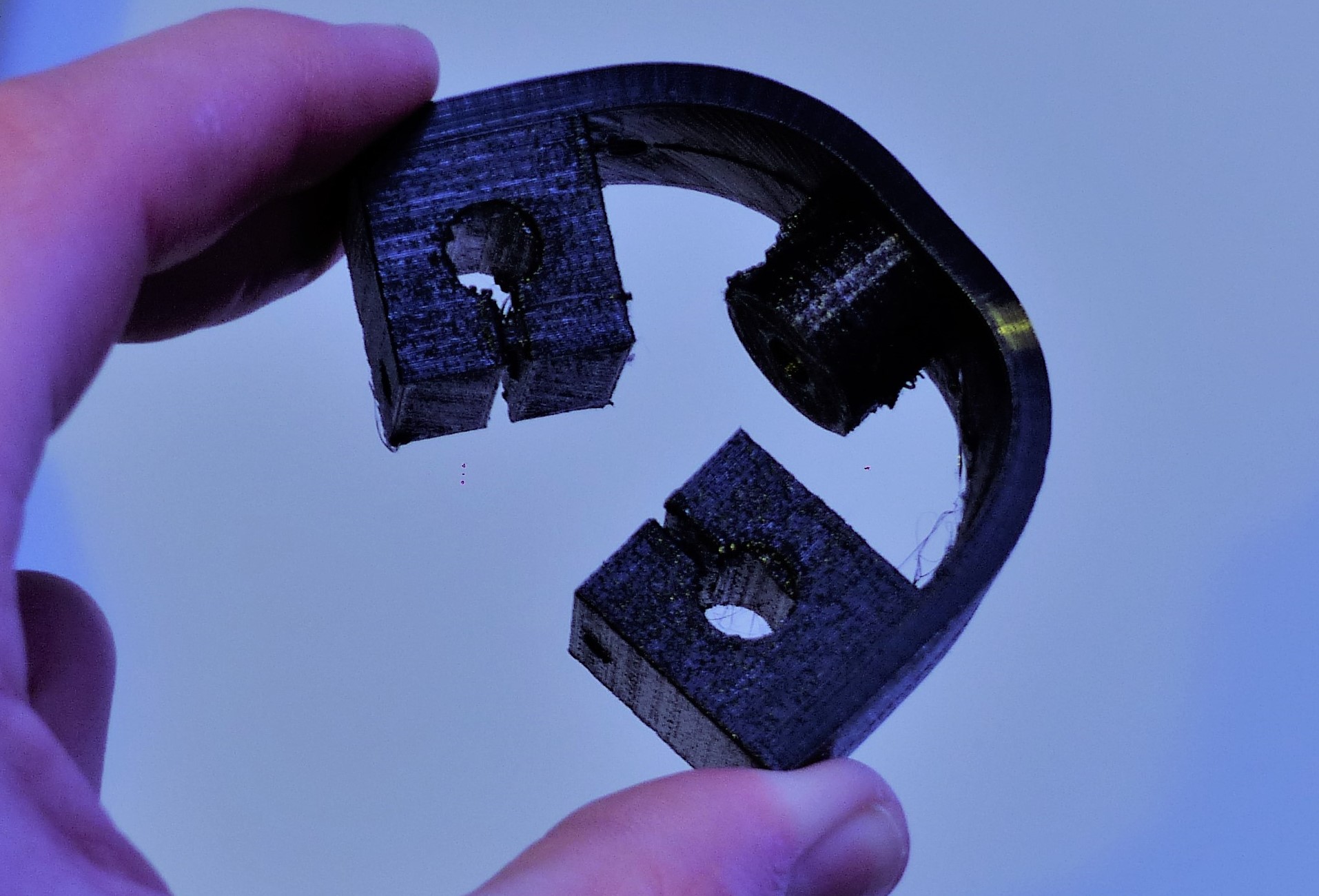

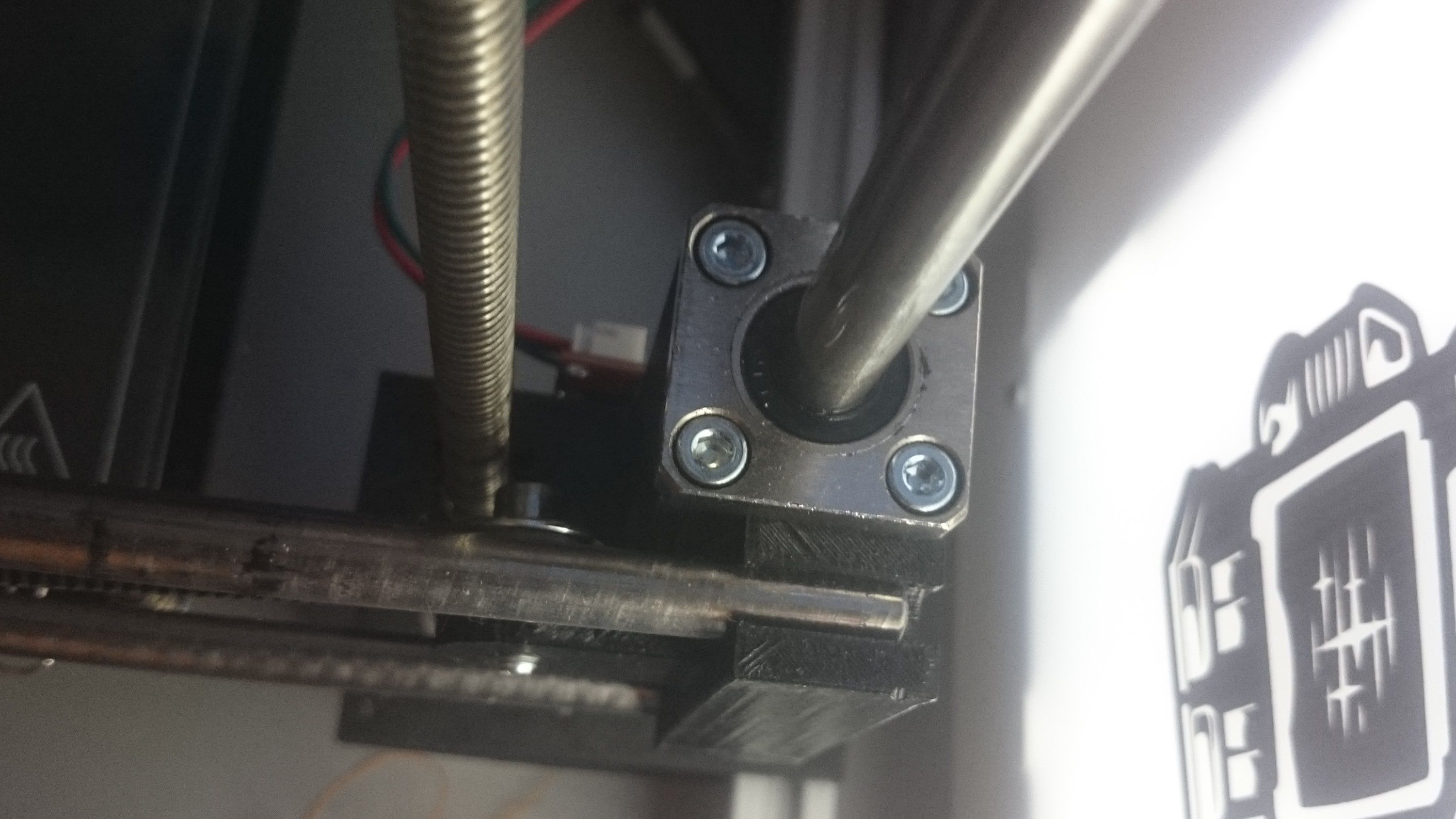

This now brings us to the part to attach the linear rods to the frame.

The part illustrated was printed with ReForm rPet filament. It holds the linear rods just fine, but the clamps are under some reasonable mechanical stress.

Although the ReForm rPet filament is very though 3D-PRINT TECH also printed a flexible version with Python Flex to have a replacement part by hand in case the previous one breaks.

3D-PRINT TECH stated that they do not have their filament profile for the Python Flex dialed in perfectly yet, but the this flexible spare part will do the job perfectly. In the meantime the print profile will be optimized.

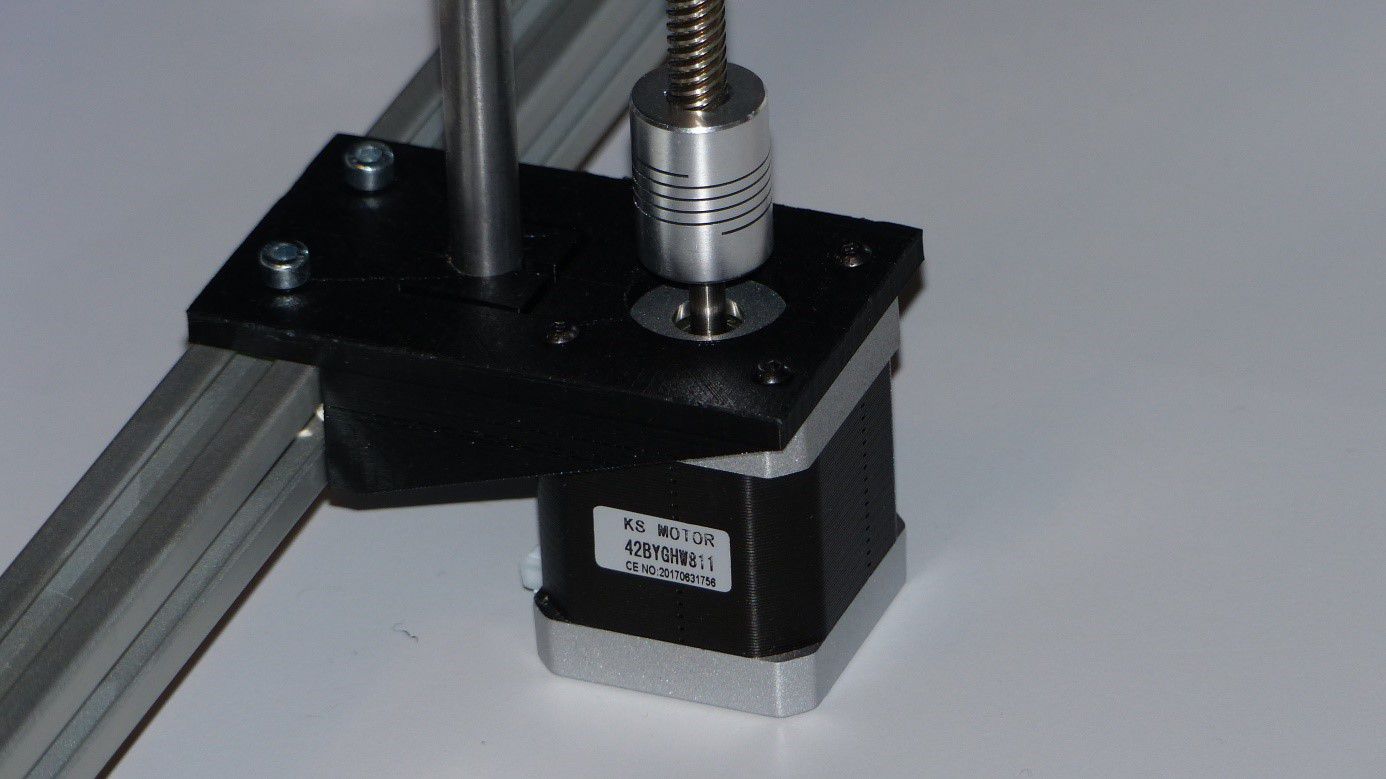

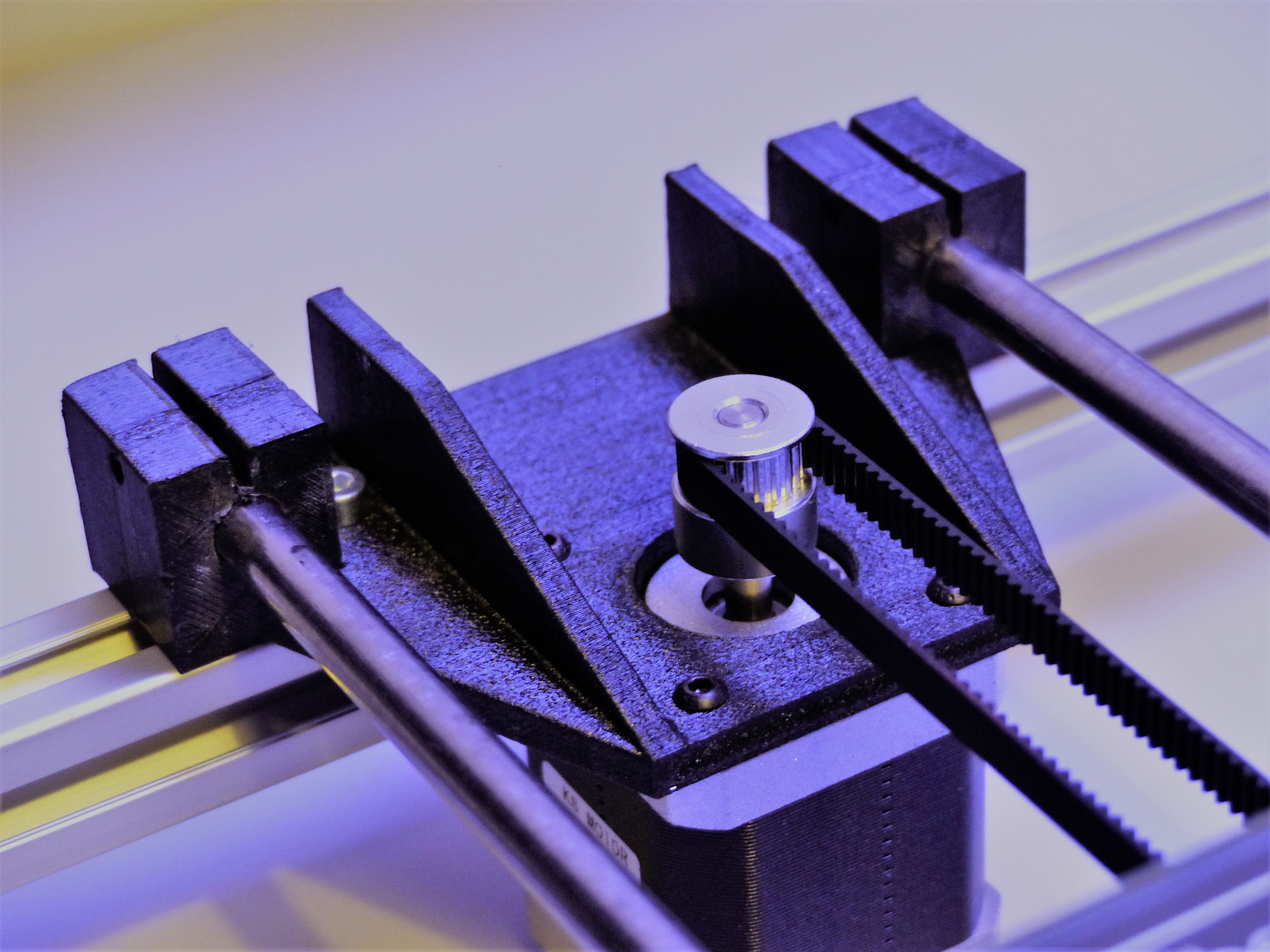

The motor mount was also printed using ReForm rPet.

Except maybe for some missed extrusion lines the surface finish of this part is great, it has a nice texture which hides the individual layer lines. The layers basically flow into each other.

The current condition of the 3D printer

For all the parts that are near the heated bed 3D-PRINT TECH chose to 3D print them with ReForm rTitan because of the great thermal resistance of TitanX.

ReForm rTitan (or TitanX) kept amazing 3D-PRINT TECH with its print quality and zero warpage, even when printing large parts.

The strength of the filament and printed parts is very important for some parts because the screw threads are self-tapped.

There is quite a lot of torque needed to insert the screw for the first time, PLA and/or PETG would for instance either crack or delaminate. This is where the strongly improved mechanical properties of TitanX are more than welcome. Below picture shows that the 3D printed parts with ReForm rTitan handled the torque perfectly.

This now brings us to the last part that was printed to complete the 3D printer project.

This part was actually not 3D printed using ReForm rTitan, but 3D-PRINT TECH selected Formfutura’s Python flex filament.

3D-PRINT TECH opted for the flexible filament because this allows for a little bit of movement of the linear rod’s.

The smallest misalignment in the frame will cause them to move a little bit and if they aren’t allowed to move, the entire axis will jam.

The great advantage of Python Flex filament is that it doesn’t need to be printed al low printing speeds, like most flexible materials. Python Flex can actually be printed at normal printing speeds.

Now the entire printer is finally complete!

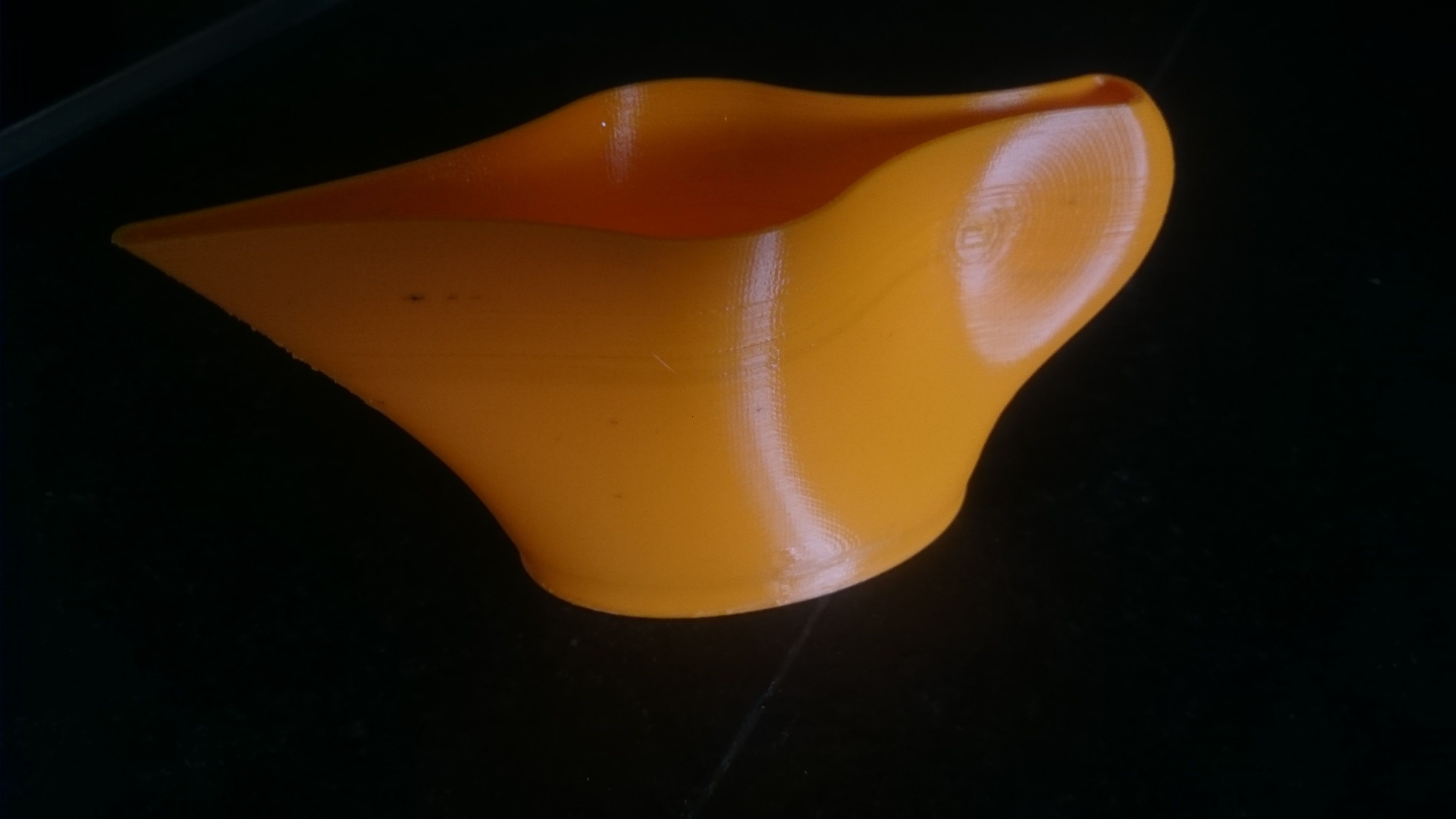

The end-result

The printer turns out to print extremely well and accurate. The print quality is great, even without a part cooling fan.

The filament used by 3D-PRINT TECH was Formfutura’s Easyfil PLA Orange. 3D-PRINT TECH actually had this spool laying around for about two years and it still print’s great….:-).

Great print quality, even without a part cooling fan.

Model: thingiverse, Small watering can by Shmeeed

Example print with the new DIY 3D printer.

Conclusion of 3D-PRINT TECH

This is my final conclusion of this project, Formfutura’s ReForm rPET (HDglass) and ReForm rTitan (TitanX) filament are great engineering materials. I used mostly TitanX because to my experience the inner layer adhesion and overall strength is better than PETG.

I was amazed by the amount of filament this project consumed, I used one and a half spool of ReForm rTitan and 3 quarters of a spool of ReForm rPET.

This could have been half of that, because I had to print most part’s two times in order to achieve the required tolerances.