Distribution collaboration between Mitsubishi Chemical and FormFutura

We are proud to announce our distribution collaboration with Mitsubishi Chemical in which FormFutura will become an official distribution partner for Mitsubishi Chemical’s portfolio of 3D printing filaments.

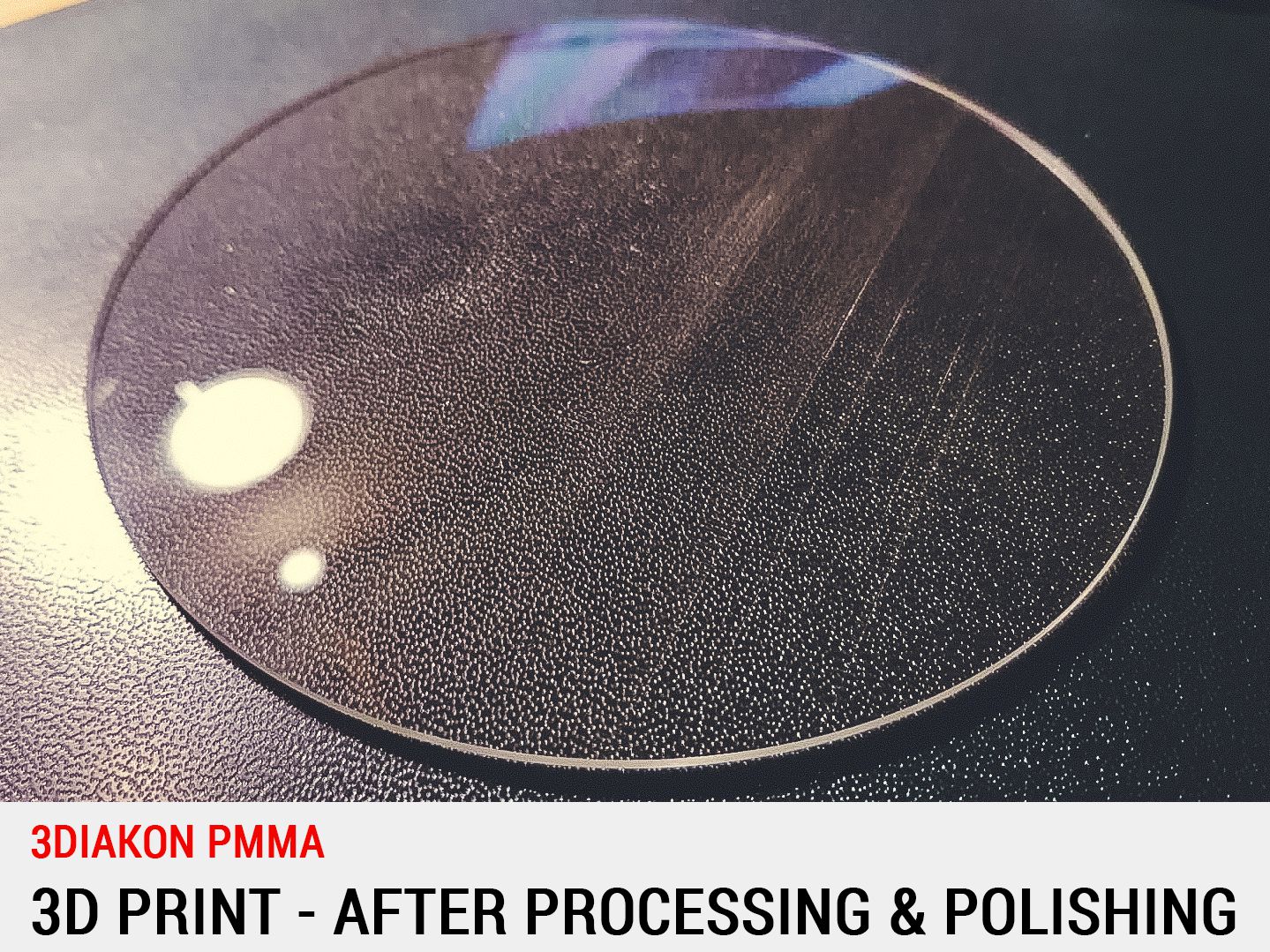

Mitsubishi Chemical has now made its performance polymers DURABIO and 3Diakon available for 3D printing applications through Fused Filament Fabrication (FFF).

DURABIO

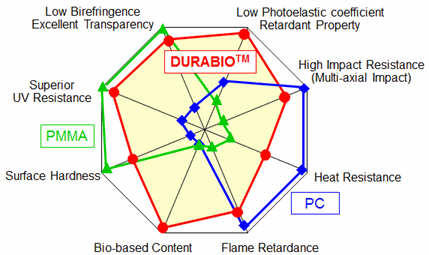

DURABIO is a bio-based engineering filament that combines most of the advantageous properties of Polycarbonate (PC) and those of Polymethyl methacrylate (PMMA), creating an innovative renewable 3D printing filament with extraordinary properties.

DURABIO is a 3D printer filament with transparency properties similar to PMMA, but with a much higher impact resistance and improved heat resistance. DURABIO filament outperforms PC for 3D printing applications that require properties such as scratch resistance, hardness, and chemical resistance. That is why DURABIO closes the gap between PC and PMMA.

This bio-based Polycarbonate (PC) 3D printing filament whose main raw material is plant-derived isosorbide is a transparent engineering plastic which has various characteristics distinct from PC filaments made from BPA raw materials. In particular, its optical properties are superior. Also light exposure stability and surface characteristics show high performance.

DURABIO is particularly designed for scratch and impact resistance applications requiring exceptional durable transparency and visual appearance.

Edgar Schoorl, Commercial Manager at FormFutura

“DURABIO and 3Diakon are two innovative performance polymers which are widely used in injection molding across various industries ranging from automotive and aerospace to healthcare and consumer electronics. As the 3D printing industry is evolving we now more and more see an application driven focus. Specific filaments are needed to unlock 3D printing applications that can replace traditional production methods and enable on site manufacturing through 3D printing.”